Automation Technology

July 11, 2024

Events

July 11, 2024Warehouse Management

From before an inbound shipment enters your gate until after an outbound shipment leaves, AE Warehouse Management solution optimizes every move – from raw materials to finished goods, and the material handling equipment and people who move them – enabling the most agile, productive and lean distribution operations possible. That means lower distribution costs and improved return on your supply chain investment.

- Mother warehouse.

- Distribution Centre.

- Inventory Management.

- Manpower Supply.

The functionality of warehouse management systems (WMS) can differ significantly from warehouse control systems (WCS). Simply put, a WMS plans a weekly activity forecast based on such factors as statistics and trends

WCS can prevent that problem by working in real time and adapting to the situation by making a last-minute decision based on current activity and operational status.

A WMS uses a data base configured to support warehouse operations, containing detail describing a variety of standard warehouse elements including the

- Individual Stock Keeping Units (SKUs) that are handled and stored, e.g., weight, dimensions, case pack, Automatic ID labels (bar codes, etc.), and inventory by location with manufacture date, lot code, etc. SKUs may include basic materials, fabricated parts, assemblies, and industrial and consumer finished goods, etc.;

- Warehouse storage locations, e.g., individual location number, picking sequence, type of use (picking, reserve storage, etc.), type of storage (each, case, pallet), location size or capacity, storage restriction (flammable, hazardous, high value materials, outdoor, etc.), etc.;

- Dock doors, e.g., individual number, etc.;

encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers. In essence, supply chain management integrates supply and demand management within and across companies. Supply Chain Management is an integrating function with primary responsibility for linking major business functions and business processes within and across companies into a cohesive and high-performing business model. It includes all of the logistics management activities noted above, as well as manufacturing operations, and it drives coordination of processes and activities with and across marketing, sales, product design, finance and information technology.

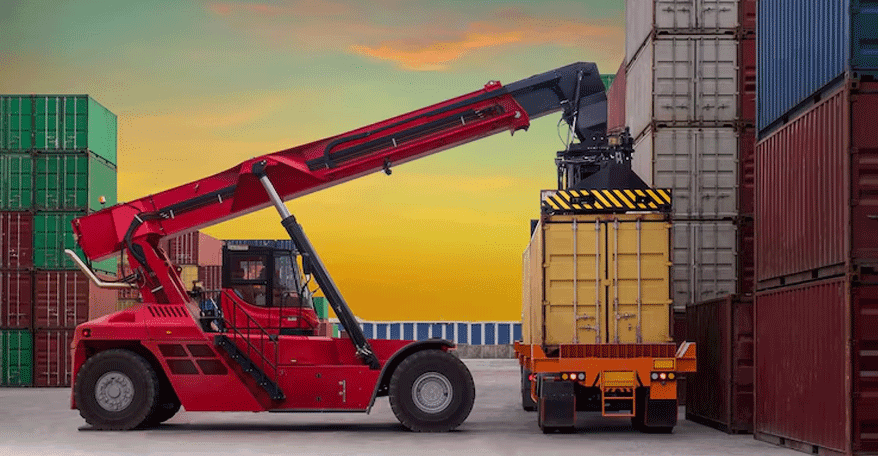

1. Warehouse and Distribution End to end Solutions.

2. Green Mobility with EV Customized Segments.

3. Primary & Secondary Distribution

4. Last Mile Distribution

5. FTL, LTL & PTL Loads Distribution Solutions.

6. Appointment Pickup and Distribution.

7. Green Mobility First Mile Operations

8. Green Mobility Last Mile Operations.

To give the real value to our customer demands, stern drives PROCURE – CONSOLIDATE – DELIVERY module to create smooth and healthy business relation between the customer and vendor, with our multimodal transport (Road, Rail and Air) expertise we will always a step ahead than our competitors to serve our customer demands on time.

- Procurement.

- Consolidation.

- Execution.

- Delivery.

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!